Empowering Predictive Maintenance: The Role of Edge Computing in the Oil & Gas Industry

Published on Mars 15, 2023

Ready for a demo of

Namla

?

Predictive maintenance (PdM) is a critical component of Industrial Internet of Things (IIoT) systems, as it enables organizations to proactively identify equipment issues before they cause unplanned downtime or safety hazards. In industrial settings, downtime can be extremely costly and can have far-reaching consequences, including reduced productivity, missed deadlines, and lost revenue.

PdM is a proactive approach to prevent downtime and optimize equipment performance, helping organizations reduce maintenance costs, increase uptime, and enhance overall efficiency. Nevertheless, traditional PdM systems rely on cloud computing for data analytics, which may lead to latency problems and security risks.

To address these obstacles, organizations are turning to PdM on edge, a distributed architecture that uses edge computing to process and analyze data closer to its source, enabling real-time analytics and reducing latency. In this article, we will discuss the benefits of PdM on edge, the key components of an edge-based PdM system, and how it is revolutionizing the Oil & Gas industry.

What is Predictive Maintenance ?

Predictive Maintenance (PdM) is a proactive maintenance strategy that involves utilizing data analytics and machine learning algorithms to predict and anticipate when machines or equipments are likely to fail, allowing maintenance teams to proactively schedule maintenance prior to any breakdown.

This approach is based on the idea that machines give off early warning signs before they fail, which can be detected through sensors that measure parameters such as temperature and vibration.

By analyzing the data from these sensors, machine learning algorithms can recognize patterns and anomalies that indicate when a machine is susceptible to failure.

Why PdM ?

The adoption of an AI-enabled predictive maintenance solution provides several competitive advantages including:

- Increased uptime

PdM helps reduce unplanned downtime by identifying potential equipment malfunctions before they occur. This results in fewer interruptions in production, higher machine uptime, and increased productivity.

- Improved efficiency

PdM plays a role in the extension the lifespan of equipment by identifying and addressing potential issues before they turn into major problems. This can lead to improved equipment reliability and reduced replacement costs.

- Enhanced safety

PdM helps identify potential safety hazards before they cause accidents. This leads to improved safety for employees and reduced liability for the organization.

In fact, in a study conducted by Deloitte, PdMs’ impact on:

- 1. Productivity: + 25%

- 2. Breakdowns: - 70%

- 3. Maintenance costs: - 25%

- 4. Equipment uptime: + 10-20%

- 5. Maintenance planning time: - 20-50%

In another study by IOT Analytics, PdMs saved organizations $18B in 2018, such amount is expected to reach $188B in 2024.

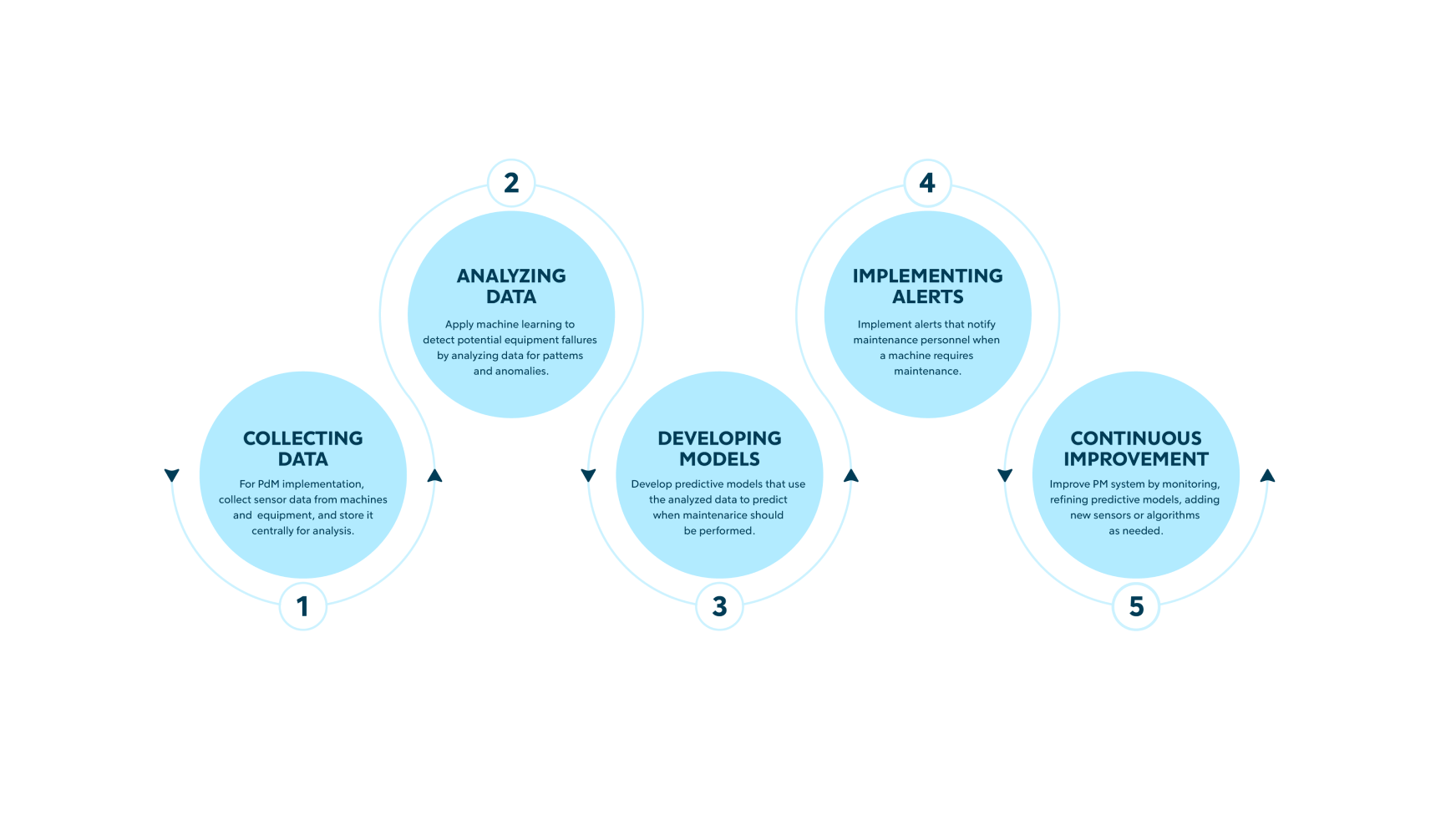

PdM System: Concept & Diagram

The implementation of the PdM strategy often goes through the following main steps:

PdM x Edge: The Future of Predictive Maintenance

Predictive Maintenance on Edge (PdM on Edge) is a distributed architecture that leverages edge computing to process and analyze data in close proximity to its source, allowing for real-time analysis for predictive maintenance in Industrial Internet of Things (IIoT) systems.

PdM systems traditionally rely on cloud computing for data analytics, but this can cause problems with latency and security. PdM on Edge addresses these challenges by processing data closer to the source, which reduces latency and improves security.

An edge-based PdM system collects data from sensors and other edge devices that are installed on machines and equipment. The data is processed and analyzed in real-time by edge computing nodes, allowing organizations to proactively identify potential equipment issues before they cause unplanned downtime or safety hazards.

PdM at the Edge: Oil & Gas use-case

The Oil & Gas sector suffers enormous financial losses from even brief instances of unplanned downtime. To evaluate and anticipate machine conditions, numerous oil and gas enterprises install IoT sensors in their equipment.

PdM on Edge can be effectively employed in the Oil & Gas industry to monitor pipelines, which are a critical component of the industry. The failure or leakage of pipelines can result in safety risks, environmental harm, and expensive downtime.

PdM on Edge enables the deployment of sensors along the pipeline to gather data, including pressure, temperature, and flow rate.

The data gathered by the sensors is analyzed in real-time with the help of machine learning algorithms to predict possible problems, like corrosion or cracks. This allows for early detection of issues, enabling scheduling of maintenance work and timely resolution of critical problems, which ultimately reduces downtime and improves safety.

Market Solutions in the Oil & Gas Industry

Outlined below are some of the most popular PdM solutions applicable in the Oil & Gas industry, along with a brief overview of their key strengths:

- Bently Nevada Asset Condition Monitoring

A comprehensive PdM system designed specifically for the oil and gas industry. By utilizing advanced analytics, real-time data monitoring, and remote monitoring, the solution enables operators to predict potential failures and proactively plan maintenance activities.

- EcoStruxure Asset Advisor

Uses predictive maintenance capabilities for optimized maintenance schedules and easy integration with other systems and applications. Read more on EcoStruxure™ solutions for Energies and Chemicals.

- GE Digital's Predix

A cloud-based platform that leverages advanced analytics and machine learning to facilitate real-time equipment monitoring, thus, optimizing the performance of oil and gas assets. It can integrate seamlessly with other systems.

- Siemens MindSphere

Offers real-time monitoring of critical assets and can be used for a variety of equipment types to extend asset lifespan, and increase overall productivity. You can learn more about MindSphere in Oil & Gas on “Apps for oil and gas” paragraph in Why digitalisation matters for oil and gas.

- Honeywell's Asset Performance Management

Uses predictive analytics to optimize maintenance schedules and provides real-time monitoring of equipment health.

- IBM Maximo Asset Management

Provides predictive maintenance capabilities for potential equipment failures and real-time monitoring of critical assets, IBM® Maximo® for Oil and Gas aims to reduce operational risk and improve asset performance while ensuring compliance with regulations.

While not all of the above systems are examples of PdM (Predictive Maintenance) at the edge, but they do include PdM as one of their key functionalities, and while not all of them deployed mainly at the edge here is their different deployment model:

What Namla Offers!

We at Namla are working on a novel PdM System for Oil & Gas Industry delivered at the Edge with:

- ● Pre-configured Edge environment

- ● Run with Namla OS

- ● Reliable SD-WAN Architecture

Namla PdM is a fully-managed services that aims to incorporating the following key points:

- ● Edge Computing

- ● Machine Learning & AI

- ● Sensor Integration

- ● Data Security and Privacy

- ● Ease of Use and Integration